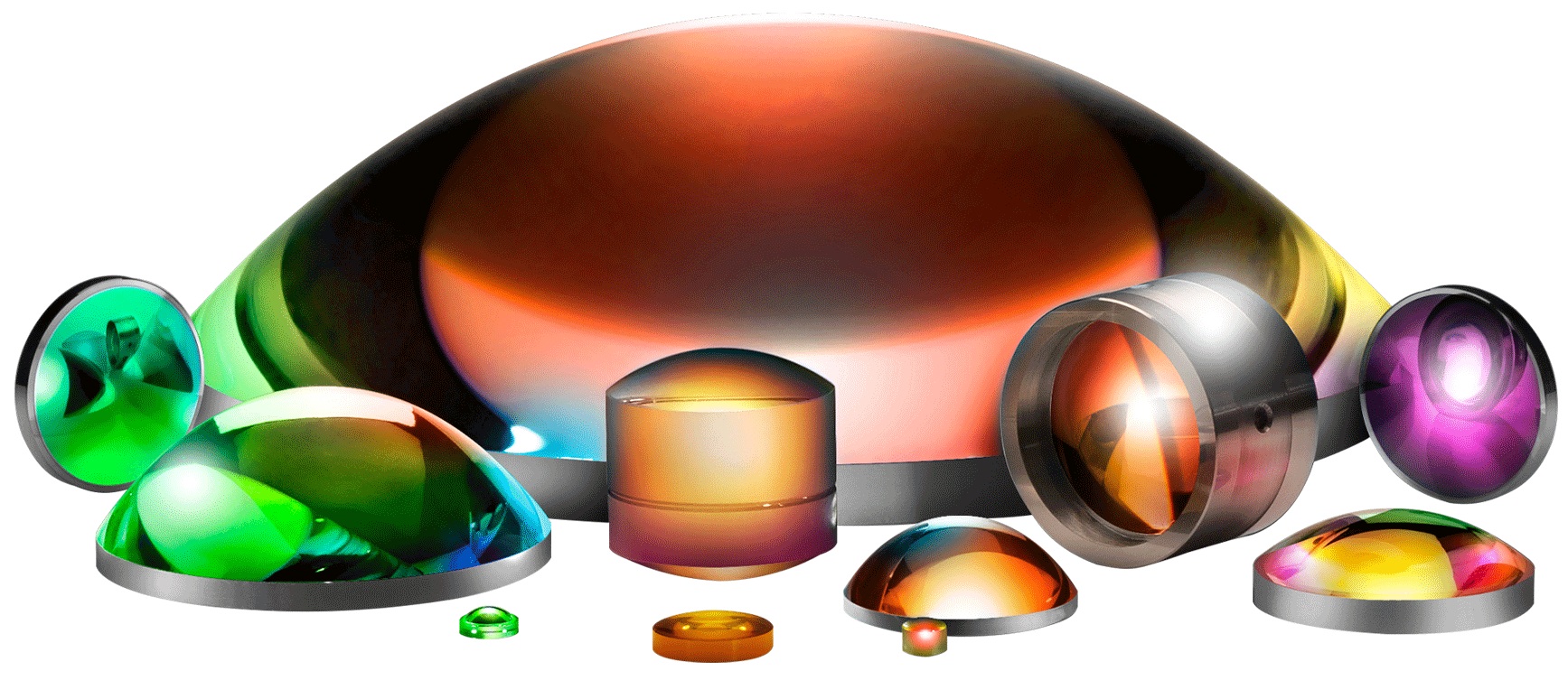

Edmund Optics® versorgt Kunden auf der ganzen Welt mit Millionen von selbst gefertigten, präzisen optischen Komponenten und Baugruppen. Wir besitzen die Erfahrung und die Fähigkeiten, um optische Produkte basierend auf Ihren speziellen Projektanforderungen herzustellen. Unser engagiertes und hervorragend ausgebildetes Team ermöglicht Ihnen die optimale Lösung für Ihre Anwendung - vom Design über Prototypen und Serienfertigung Ihres kundenspezifischen Produkts bis zur Vermessung und Qualitätssicherung nach dem neuesten Stand der Technik.

Edmund Optics® unterstützt seine Kunden vom Prototyp bis zur Serienproduktion und ist darauf spezialisiert, kostengünstige Lösungen zu schaffen, die den Spezifikationen, Zeitvorgaben und Budgets der Kunden entsprechen.

Edmund Optics® erweitert kontinuierlich seine Ausstattung und Werkzeuge, um optimal alle Kundenwünsche erfüllen zu können.

Wir haben Standorte in 12 Ländern, 8 Fertigungen, 6 globale Distributionszentren, 4 hervorragende Entwicklungszentren und 7 Labore. Mit unseren globalen Standorten und der Präsenz vor Ort bieten wir sachkundige Anwendungsunterstützung und arbeiten direkt mit unseren Kunden an Lösungen für ihre spezifischen Projekte. Kontaktieren Sie unsere Ingenieur*innen vor Ort, die über große Kunden- und Anwendungserfahrung verfügen und Ihnen bei Ihren speziellen Anforderungen gerne weiterhelfen. Sie finden nicht das, was Sie benötigen? Nutzen Sie unsere Erfahrung für Ihre nächsten Projekte - unser Team ist motiviert und engagiert und stets bereit, eine Lösung für Ihre Herausforderungen zu finden und kundenspezifische Produkte zu entwickeln. Bei Edmund Optics® tun wir, was das Beste für unsere Kunden ist.

7.150 m2 Fertigungsfläche. Vertikal integrierte Fertigung für Serien von Komponenten und gefassten Optiken.

7.430 m2 Fertigungsfläche. Hochpräzise Sphären, Prismen und andere beschichtete Optiken mit über 50 Jahren Erfahrung.

11.150 m2 Gesamtfläche; 1.860 m2 Fertigungsfläche. Hochpräzise Fertigung, Beschichtung, Assemblierung und Tests.

3.159 m2 für die Herstellung von Beschichtungen mit hoher LDT, Laserkristallen und anderen hochpräzisen Optiken.

660 m2 Gesamtfläche; 7.060 m2 große Einrichtung. Europäischer Produktionsstandort für Polarisatoren und farbige Filtergläser sowie Sitz des europäischen Optikdesign-Services.

1.500 m2 Fertigungsfläche. Unterstützung des Werks in Singapur bei Serienproduktion von Sphären & Prismen.

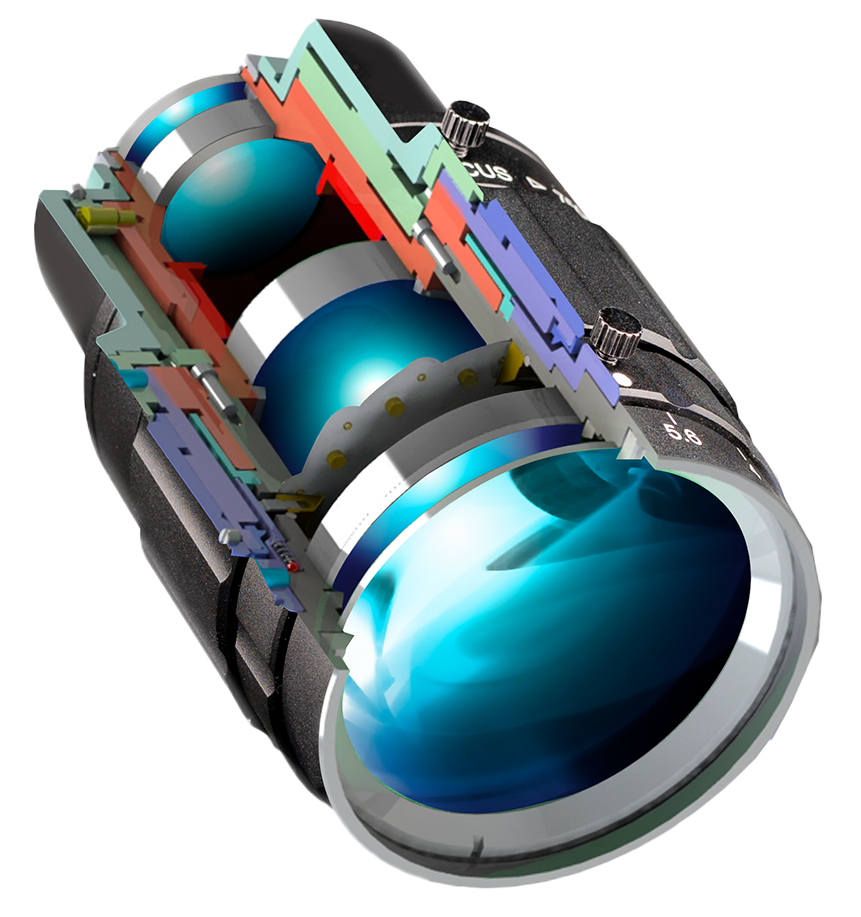

1.500 m2 Fertigungsfläche. Design, Assemblierung und Tests von Optomechanik-Baugruppen und Objektiven in Serie.

1.972 m2 für Assemblierung von Optoelektronik-Baugruppen, Objektivdesign, Optikvermessung.

Optische Beschichtungen sind ein wichtiger Bestandteil der fertigen optischen Komponenten oder Baugruppen. Eine präzise Planung und Fertigung ist ausschlaggebend für die Haltbarkeit und Lebensdauer der Komponenten im Einsatz. Edmund Optics verfügt über Möglichkeiten und Erfahrung, um Beschichtungen für Life-Science- und Medizinanwendungen, raue Umgebungen und Anwendungen im ultravioletten (UV), sichtbaren (VIS) sowie infraroten (IR) Spektrum zu fertigen. Alle Optiken werden genauestens im Reinraum gesäubert, beschichtet, inspiziert und hinsichtlich der Kundenanforderungen (Umgebung, Wärme, Beständigkeit) überprüft.

Messtechnik ist eine wichtige Voraussetzung für die Lieferung von zuverlässigen kundenspezifischen Produkten. Nur wenn etwas messbar ist, ist es auch herstellbar. Bei Edmund Optics kombinieren wir eine große Auswahl von Messtechniken und Werkzeugen, die speziell für Ihre Bedürfnisse einzeln oder in Kombination eingesetzt werden können - Ihre Anforderungen definieren unseren Prozess.

Bei jedem Schritt legt Edmund Optics großen Wert auf die Sicherstellung der Produkt- und Prozessqualität und verfügt über eine nachgewiesene Erfolgsbilanz bei maßgeschneiderten Tests für optische Baugruppen, die auf die Projektanforderungen zugeschnitten sind.

Bei Edmund Optics erstellt ein Expertenteam aus Designern für Optik und Optomechanik, Projektmanagern und Fertigungsingenieuren eine Vielzahl verschiedener Optomechanik-Baugruppen.

Die Ingenieur*innen von Edmund Optics® entwickeln komplett kundenspezifische Komponenten, fertigen nach Kundendesign oder erstellen schnelle Modifikationen für Tausende über unseren Onlineshop verkaufte Optiken.

Unser hausinternes Fachwissen und unsere Messtechnik zur Unterstützung Ihrer kundenspezifischen Fertigung reicht von Design & Beratung über Prototypenerstellung bis zu vielfältigen Tests.